For consumers in Kenya, freshness is one of the top considerations while purchasing food items, especially produce, meat, dairy and seafood. Urbanization, rising incomes, and greater health consciousness are making quality demands even more stringent. For distributors handling vast volumes of perishable goods, preserving optimal freshness from when produce is harvested or animal proteins processed to its point of final retail sale is pivotal but challenging. However, through a combination of cold chain infrastructure investments, real-time monitoring systems, efficient logistics, and technology partnerships, Kenyan companies are equipping themselves to deliver the freshness that consumers desire.

Common Pitfalls that Compromise Freshness

As they work to enhance their freshness preservation capabilities, some common issues faced by Kenyan food distribution firms include:

- Gaps in Temperature Control

Lack of consistent and appropriate temperature control across entire supply chains frequently leads to faster deterioration and spoilage of perishable foods. This results in losses.

- Overstocking of Inventory

Distributors sometimes overstock inventory to avoid stockouts. But higher volume and slower turnover means many products may exceed shelf lives in warehouses before reaching retailers. Prevention systems are inadequate.

- Inefficient Transportation Routes

Suboptimal planning of transportation routes and movement of goods often leads to excessive transit times. Delayed deliveries mean many products are already past peak freshness when received by outlets, diminishing shelf life.

- Poor Last Mile Connectivity

While long-haul routes are efficient, inefficiencies in last-mile delivery to outlets, especially in smaller towns, remains an issue. Unreliable final delivery compromises quality.

- Lack of Real-Time Monitoring

Most distributors lack capabilities to track variables like time, temperature, humidity etc. and monitor freshness in real-time across their operations. This blindness hampers preventive actions.

- Low Focus on Sustainability

With limited attention to sustainability, excessive plastic packaging waste is created while fuel efficiencies remain suboptimal. This increases environmental impact. Operational costs for distribution firms also rise.

Central Challenges in Maintaining Optimal Freshness

Some inherent challenges make preserving freshness across complex food supply chains difficult:

- Very Limited Shelf Life

Many products like meat, dairy, berries etc have extremely limited shelf lives of just a few days before spoiling. This requires careful handling and rapid turnover. Kenya’s tropical climate further accelerates spoilage.

- Diverse Environmental Conditions

Goods pass through diverse environments like cold storage warehouses, open trucks, small shops etc. Maintaining ideal temperature, humidity etc in each is difficult. Lack of control causes faster deterioration.

- Growing Quality Demands

As consumer awareness and incomes rise, demands for very high and consistent quality are increasing. Even minor freshness deviations can turn off buyers in a competitive landscape.

- Complex Multi-Stakeholder Ecosystems

With numerous farmers, brokers, distributors, processors and retailers involved, coordination and freshness focus across all nodes is challenging. Accountability is fragmented.

- High Logistics Costs

Investments required to provide end-to-end refrigerated storage and transportation to guarantee freshness substantially increase logistics costs. Improving cost-quality trade-offs is difficult.

- Limited Technology Adoption

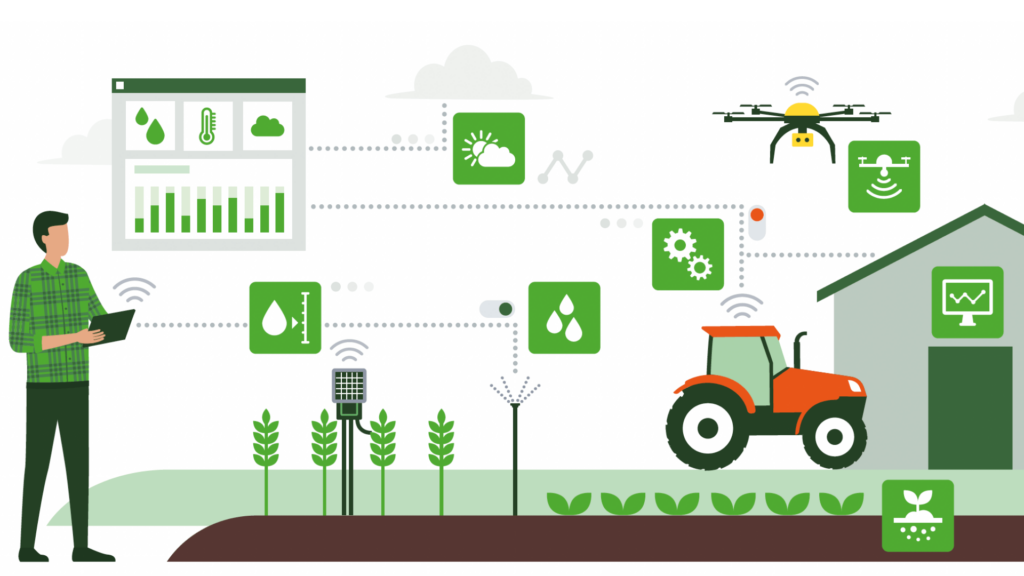

Though innovations exist, adoption of emerging technologies like blockchain, IoT sensors, mobile supply chain apps that can bolster freshness remains low. Internal resistance and high costs deter firms.

6 Strategic Interventions to Address Freshness

To proactively combat these hurdles, experts recommend Kenyan companies undertake the following initiatives:

- Strategy 1: End-to-End Temperature Control

Invest to ensure consistent temperature control across the entire supply chain, right from produce aggregation at farms through storage and delivery. Refrigerated fleets and compartments for different products prevent fluctuations.

- Strategy 2: Enhanced Demand Forecasting

Rather than depend on intuition, adopt scientific demand forecasting leveraging past sales data, inventories, weather predictions etc. to optimize procurement and stocks. This minimizes excess inventory and waste.

- Strategy 3: Efficient Route Optimization

Design transportation routes between warehouses, distribution hubs and retail outlets using route optimization algorithms to minimize transit times. This reduces delivery windows to ensure fresher handovers.

- Strategy 4: Integrated Mobile Tracking

Equip fleets with mobile apps and IoT sensors to enable real-time monitoring of location, temperature, humidity and product condition. Alerts on deviations enable quick response.

- Strategy 5: Eco-Friendly Packaging

Deploy optimal sustainable packaging like breathable films, vacuum packaging, modified atmosphere packaging and antibacterial solutions tailored to specific products. This slows deterioration.

- Strategy 6: Future-Ready Infrastructure

While upgrading current infrastructure, also design storage, handling systems, and fleet capacity focused on emerging needs like e-commerce order integration and more SKUs from fresh product lines.

Government Regulations and Industry Collaboration

Both public and private sector stakeholders in Kenya’s food ecosystem enable the freshness focus through:

- Stringent food safety regulations, quality certification, cold chain audits and produce grading systems set benchmark standards for industry players to adhere to.

- Training programs help distributors adopt global best practices around procurement, storage design, quality assurance and waste reduction to enhance freshness.

- Research initiatives by bodies like KALRO provide data, innovations and technologies tailored for Kenyan crops, climates and supply contexts to retain maximum freshness.

- Collaboration between farms, distributors, and retailers on forecasting, transparent tracking, and aligned incentives allows holistic freshness maximization.

- Inducing competitions to recognize distributors excelling in freshness preservations encourages innovation sharing across companies to collectively uplift standards.

Leveraging Emerging Opportunities

Kenyan firms can also leverage evolving spaces to unlock freshness potential:

- Sustainable Packaging

Use of compostable bio-materials, eco-friendly insulation and biodegradable modified atmosphere packaging enables freshness retention while meeting environmental goals.

- Local Sourcing

Partnering with Kenyan farms in proximity and counties supporting agro-industrialization provides access to fresher produce by reducing distances and transit time from farms.

- Direct Retail Engagement

Exploring direct retail supply partnerships and online D2C models allows distributors to bypass intermediaries and gain greater control over storage and movement to retail.

- Tech-Driven Business Models

Leveraging digital platforms for procurement aggregation, e-commerce fulfillment and app-based deliveries enables optimization of the freshest assortments. Big data analytics also drive efficiencies.

Global Success Story: Japan’s Obsession with Freshness

Japan exemplifies global best practices in maintaining high standards of freshness across all foods:

- Stringent cold chain requirements enforced through policies ensure consistent and meticulous temperature control across distribution.

- Food distributors tap innovations like precooling systems and specialized reefer containers tailored for key products like tuna to retain perfect freshness.

- Route optimization leveraging delivery density algorithms and proximity of FDI approved zones minimize transit times from processing plants to retail.

- Packaging expertise ensures techniques like vacuum packing or converting bulk to single servings retard spoilage while also addressing changing consumer lifestyles.

- AI and ML-powered demand planning coupled with Just-In-Time logistics minimizes inventory levels, reducing waste from excess stock.

The Road Ahead for Kenya’s Food Distributors

As consumer expectations around freshness rise, food companies in Kenya will need to continually uplift their capabilities:

- Make freshness preservation a key performance metric with management accountability and rewards linked to measurable KPIs on waste reduction, stock turns and product consistency.

- Proactively seek global partnerships with fridge and cold storage manufacturers, fleet companies and packaging firms to access purpose-built solutions for the Kenyan market.

- Tap emerging technologies like blockchain for traceability, IoT sensors to enable real-time monitoring, and temperature-regulated mobile delivery systems in a phased manner.

- Lobby the government for policies like fiscal incentives for cold storage infrastructure, graded motorway access for fresh fleets and food research funding that collectively uplift freshness capabilities.

- Collaborate with farms right from varietal selection and harvest planning guided by real-time sales data to boost nutrition content and naturally extend shelf life.

The combination of rising health awareness and greater purchasing power is making the Kenyan consumer more discerning when it comes to freshness.

For food companies, this poses both a challenge and opportunity. By embracing innovation, sustained investments, and collaborative thinking, freshness can be a key differentiator that unlocks new markets and builds consumer loyalty.

The future for distributors who lead the freshness transformation is certainly a promising one!

#FoodDistribution #Freshness #SupplyChain #Sustainability #ConsumerExpectations 🍏🚚🌱

About The Author

John Kariuki – Managing Director, CoolPro Logistics

John Kariuki is an supply chain expert with over 15 years of experience advising leading FMCG and food distribution companies across Kenya on efficient logistics and quality assurance. He is passionate about leveraging emerging technologies to strengthen agriculture to retail linkages.